Broomcorn as viewed in-line with the rows, or "with-row". Use the split-rail fence as a growth gauge in the following pictures.

Looking "cross-row". Plants "hilled" for the first of a couple of times.

Using a two wheel push cultivator dirt is hilled in toward the plants. This allows for better root development making for better plant stability.

A closer look at the plow attachments. Also notice the cultivators arched frame that passes over the young plants. Later hilling is done from each side using a different tool.

With-row

Cross-row

Big, broad leaves; same as Ear, or Indian corn.

Cross-row

Plants are now as tall, or taller, than the fence.

Fence is barely visible.

"Fence side," looking toward garden shed

Now with planting, cultivating and hilling of the Broomcorn finished it's "lay-by" season. Plants are tall and large enough to shade out weeds. Now we leave the plants to their business of growing and wait for harvest time. Tools are temporarily put away until the fall garden is put in.

Same location, looking at garden shed; only roof is visible.

Plants are now six to seven feet in height; no more fence viewing from this direction.

Looking toward garden shed.

Lots of "Brush" tops in view.

The brush emerging from several plants at varying stages of maturity.

Beautiful ornamental plant as well.

Broomcorn At Twelve to Fourteen weeks

(Ready for Harvest)

The next four pictures were taken in the 1940's and illustrate the broomcorn harvesting process.

Broomcorn in the field.

The harvesting begins with a process called "Tabling". The plants of two rows are bent over, toward each other forming what is called a "Table". Workers move through the field row after row "tabling".

The broomcorn is cut and loaded on wagons to be taken to the thrasher.

The seedhead, or Brush, is stripped of seeds during the thrashing process.

Broomcorn seed head before the threshing process

Broomcorn seed head after the threshing process

Broomcorn Brush Arrives At The Shop

After processing and going through a length sizing machine, the broomcorn is baled into like sized length from 12 to 22 inches. This is the way they arrive at the shop. Pictured here are two, each weighing approximately 125 lbs.

The bales are made up of approximately twenty smaller five pound bundles.

Broomcorn Brush In The Hands Of The Broom Maker

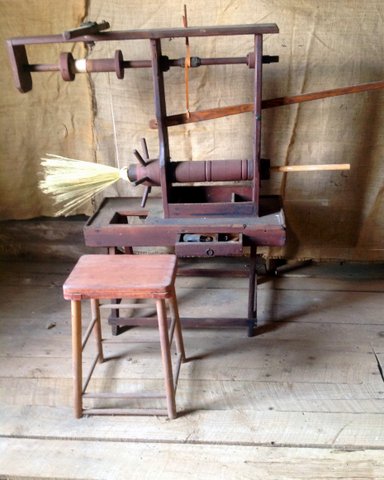

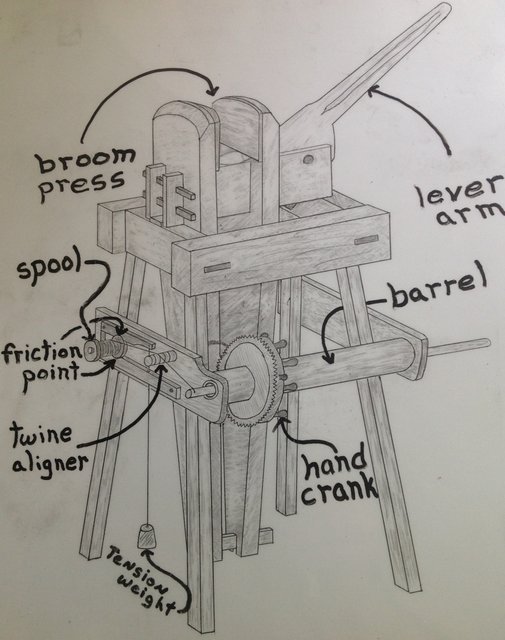

After sorting into smaller handful size bundles and immersing into warm water in order to soften, the broomcorn is ready to attach to the broom handle at the winder

The steps of the binding procedure.

Attaching broomcorn to the handle

Attaching broomcorn to the handle

Flattening and stitching at the broom press

Ready for the floor